Types of Pumps Used in the Oil and Gas Industry

Pumps are an essential component of the oil and gas industry. From delivering oil from the ground to a ship, oil refinery, or storage to speeding up the fluid flow from one point to another, pumps are used in various ways in the oil and gas industry.

Each type of pump in a refining system serves a distinct job and is essential for daily operations. Without pumps, oil refineries would be unable to function at total capacity on a daily basis.

In this article, we will look at the various types of pumps used in the oil and gas industry, as well as what pumping applications they serve in their respective situations. Continue reading below to learn more about which types of pumps can help improve your company’s daily operations and how C&B Equipment can help you make your business run more efficiently.

10 types of industrial pumps used in the oil and gas industry

Pumps are used in a variety of sectors of the oil and gas industry. Not only do these pumps carry oil and other fluids to their respective destinations, but they all also operate on the same basic principles. However, there are some variances depending on the industry and application.

Choosing the right pump for your business is a critical decision to make. Let’s take a look at ten of the most common pumps used in the oil and gas industry and how each one works.

Centrifugal pumps

Centrifugal pumps are the most common type of industrial pump used in the oil and gas industry. Centrifugal pumps contain one or more rotating impellers that suck fluid into the suction end of the pump before forcing it out the discharge end using centrifugal force.

Pumps with this design may be utilized in a wide range of pumping applications and are particularly well suited to handle filthy or low-viscosity liquids, as long as they don’t contain air, fumes, or large amounts of particles.

Recommended Read C&B Equipment’s Guide to Multistage Centrifugal Pumps

Oil transfer pumps

When there isn’t enough ground pressure to propel the oil to the surface, an oil pump manually pumps liquid out of an oil well. Oil transfer pumps are powered by a motor that generates vertical motion to drive the pump shaft, referred to as a ‘walking beam.’

Oil transfer pumps are generally utilized in onshore regions where there is a lot of oil, but the ground can’t get it out, and, depending on the depth and weight of the oil, these pumps may deliver one to ten gallons of petroleum with each stroke.

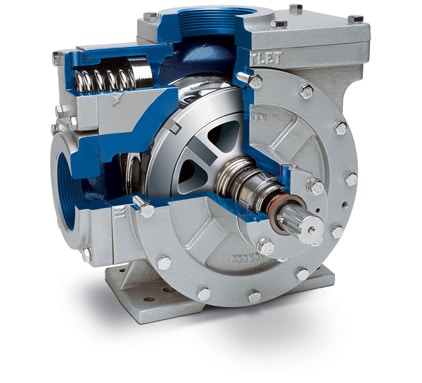

Positive displacement pump

Positive displacement pumps, unlike centrifugal pumps, do not require impellers to move the fluid. Instead, they use spinning or reciprocating elements to drive the liquid into a contained space.

This design provides pressure, which causes the liquid to flow to its intended location, to push fluid into a confined compartment utilizing spinning components. Positive displacement pumps are designed to transport very viscous liquids at a lower flow rate but with a much higher pressure.

Diaphragm pump

During the upstream and midstream phases of crude oil refinement, a diaphragm pump is used to pull oil into the refinery chamber. It employs both a valve and a diaphragm.

When the volume of a chamber grows, the pressure inside the chamber decreases, and the fluid pours in. The liquid is then forced out when the diaphragm goes down. The diaphragm returns to its original position once the fluid has cleared the chamber, allowing new fluid to enter.

Petrochemical pump

Petrochemical pumps work at high pressure and high flow rates within a refinery system to treat or refine compounds. One of the advantages of petrochemical pumps is that they avoid leaks, which means they protect the environment. The petrochemical pump’s simple design, ease of use, and compactness provide it with the durability it needs to keep up with the rigors of oil drilling.

Recommended Read Types of Pumps Used in the Pharmaceutical Industry

Reciprocating plunger pumps

Reciprocating plunger pumps are among the most common types of pumps used in the oil and gas industry. Plunger pumps pressurize fluid in an enclosed cylinder to a pipe system using the reciprocating action of plungers and pistons. Plunger pumps are known as constant flow pumps because the flow rate remains consistent regardless of the system pressure at any given speed.

Progressive cavity pumps

A progressive cavity pump is a type of pump that moves fluid by turning its rotor, which causes a series of tiny, fixed-shape, discrete chambers to move through the pump. Whatever the system pressure, the flow rate remains practically constant at a given speed. Progressive cavity pumps are utilized in high viscosity applications or where it is not necessary to mix the pushed fluid.

Recommended Read What Is a Progressive Cavity Pump?

Gear pumps

For transferring industrial fluids, gear pumps are one of the most prevalent types of positive displacement pumps. A gear pump pumps fluid by using the meshing of gears and is often utilized for clean fluids since the pushed fluid passes between the narrow gear tolerances. A relief valve is an integral part of the discharge pipe system because it protects the pump and the pipe from being over-pressurized.

Metering pumps

The phrase “metering pump” refers to the delivery of fluids at exact, controllable flow rates. As such, a metering pump transports a specific amount of liquid in a predetermined amount of time, resulting in a precise flow rate. Reciprocating pumps with a packed plunger or diaphragm liquid end make up the majority of metering pumps.

Recommended Read Your Guide to Choosing the Right Chemical Dosing Pump

Booster pumps

Lastly, booster pumps are used for various applications in the oil and gas industry, come in a variety of styles, and can handle both liquid and gas. The design of booster pumps varies depending on the fluid and uses a single-stage compression mechanism that may also be used to raise the pressure of a gas that is already above ambient pressure.

You can trust C&B Equipment to meet your business’s needs

Pumps are a cost-effective way to move chemicals, and each of the pumps described above has a distinct role in the oil and gas industry for transferring or purifying various fluids.

Are you interested in learning more about how a specific pump can benefit your business operations? At C&B Equipment, we know how different types of pumps function for diverse applications in the oil and gas industry.

Engineered solutions and dependable, efficient products are at the center of what we do at C&B Equipment. Our comprehensive selection of pumps gives your business the most cost-effective and efficient solutions. With extensive knowledge and years of expertise, we are proud to offer our customers top-of-the-line industrial equipment for their companies.

To learn more about how C&B Equipment can help your business improve its efficiency and find the pump that is best suited for your business operations, contact us today to request a consultation with one of our qualified customer service representatives.

Take a look at our selection of industrial pumps!

or

Take a look at our preventative maintenance, repair, and installation services!