What Is a Progressive Cavity Pump?

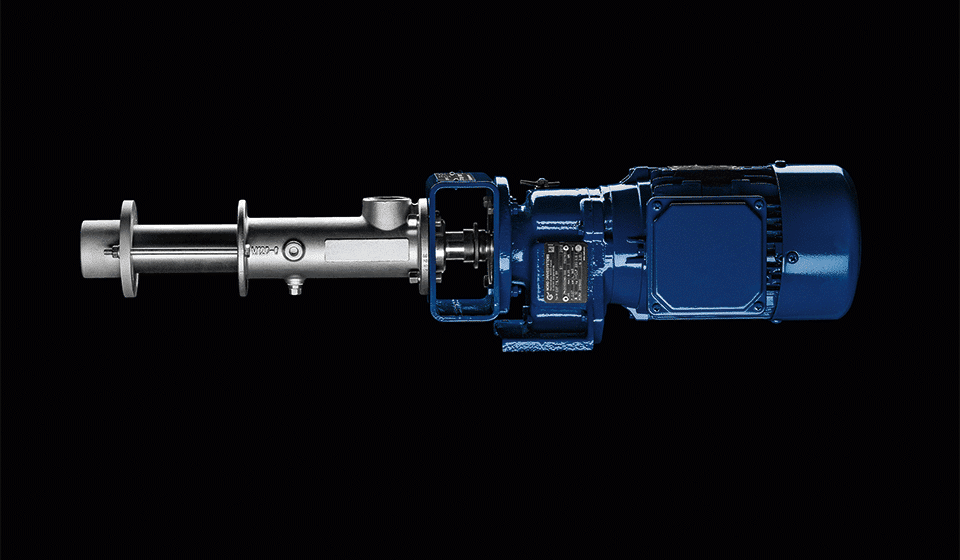

A progressive cavity pump is a type of positive displacement pump that is designed to handle extremely tough pumping applications and high viscous fluids.

While it is a versatile pump that can handle a variety of jobs, it is perfectly designed for metering chemicals and pumping viscous, abrasive, or shear-sensitive materials.

Other terms for progressive cavity pumps include progressing cavity pumps, PC pumps, cavity pumps, and progg cavity pumps.

Take a look at the industrial pumps offered by C&B Equipment!

How does a progressive cavity pump work?

Like all positive displacement pumps, progressive cavity (PC) pumps are flow-creating devices. They move fluid at a consistent speed regardless of the pressure on the inlet end.

PC pumps draw fluid in through a suction inlet which feeds into an elongated casing. Within the casing are a helical rotor and stator assembly. The rotor helix is offset to the stator. As the rotor turns and contacts the surface of the stator, a series of small cavities begin to form.

The fluid “progresses” through these cavities until it is expelled through a discharge outlet.

PC pumps cannot be allowed to run dry, as the heat generated by the rotor and stator can cause pump failure. A lot of PC pumps utilize accessories that act as a safeguard against this.

Additionally, progressive cavity pumps are self-priming, have a higher pressure per stage than many other positive displacement pumps, and also have a high suction lift.

Recommended Read Centrifugal vs Positive Displacement Pumps: What’s the Difference?

What purposes do progressive cavity pumps serve?

Progressive cavity pumps are used to pump fluids that cannot be handled by other types of industrial pumps. They typically serve the following purposes.

- Pumping, dosing, and metering chemicals

- Pumping shear-sensitive materials

- Pumping materials that contain abrasive particles

- Pumping heavy or viscous fluids

- Pumping fluids in applications that require varied flow rates

Pumping, dosing, and metering chemicals

The cavities inside a PC pump taper at their ends and overlap, so there is no flow pulsing other than that caused by compression of the pump components or fluid. It is this smooth, low-pulsation pumping that makes PC pumps so well-suited to metering applications.

The flow rate of PC pumps is proportional to their speed, so they can be used to dose high viscous fluids such as additives and chemicals.

Recommended Read Your Guide to Choosing the Correct Chemical Dosing Pump

Pumping shear-sensitive materials

The volumetric flow rate of a PC pump is proportional to its rotation rate. This applies very little shear to the pumped fluid. This feature, along with a lower internal velocity, makes PC pumps ideal for pumping shear-sensitive materials, such as fluids that contain fragile solids.

Pumping materials that contain abrasive particles

In other pump designs, fluids travel around the inside walls of the casing at high speeds. When the pumped material contains abrasive solids, this “scours” the pump’s surfaces and causes it to wear out before the end of its useful lifespan.

A progressive cavity pump, on the other hand, takes the fluid through a long casing. The abrasive particles travel parallel to the internal surfaces at a slower speed, as opposed to being hit centrifugally at a high speed.

PC pumps are far more abrasion-resistant and last a lot longer than other types of pumps when used for these specific applications.

Pumping heavy or viscous fluids

Progressive cavity pumps are ideal for pumping fluids that have higher viscosities. With a centrifugal pump, the flow rate goes down as the fluid viscosity goes up. This is far less efficient, as the pump must then increase its energy consumption in order to keep up.

PC pumps, like other types of positive displacement pumps, create their own flow. A PC pump is actually more efficient as viscosity increases and will have approximately the same flow rate no matter the weight of the pumped material.

Pumping fluids in applications that require varied flow rates

PC pumps produce a precise flow per revolution, making it easy to manage the pump flow by simply regulating the pump speed. They pair well with variable frequency drives for managing flow rates.

Likewise, PC pumps can be used when you need a steady flow, but the viscosity of the pumped fluid is variable.

What are some specific applications of progressive cavity pumps?

Progressive cavity pumps are used for a wide variety of applications, including the following.

- metering and dosing

- wastewater

- chemical manufacturing

- oil pumping/petroleum production

- food and beverage processing

- pulp and paper

- environmental technology

- sewage, sludge, and slurry pumping

- grout or cement pumping

- limited energy well water pumping

- lubrication oil pumping

Recommended Read A Guide to Inline Pumps, Applications, and Uses

Locate your ideal progressive cavity pump with help from C&B Equipment!

C&B Equipment is one of the nation’s leading distributors of industrial pumps, blowers, motors, and engines. We offer some of the best progressive cavity pumps available on the market, manufactured by reputable companies like SEEPEX and Roper.

We can help you determine which type of industrial pump is the most suitable for your industrial needs. In addition, we also offer a number of industrial equipment-related services, including repairs, preventative maintenance programs, installations, and audits.

Take a look at the industrial pumps we have to offer!

or

Take a look at our repair, maintenance, and installation services!