How to Increase Centrifugal Pump Efficiency

Most businesses are looking at ways to trim costs, become more energy efficient, and improve overall results. Companies are using sensors to monitor equipment, changing times of operation, and even upgrading their solutions.

If your business needs to transfer liquid from one place to another, it probably uses centrifugal pumps. These come in a variety of sizes, and they are highly versatile. However, they also consume a ton of energy. Pumps consume more energy in chemical plants than any other type of equipment.

Whether your business operates one pump or two hundred, it’s critical that these pieces of machinery operate at the highest efficiency levels possible. Here’s what you need to know about centrifugal pumps and how to increase their efficiency.

What Is a Centrifugal Pump?

What Is a Centrifugal Pump?

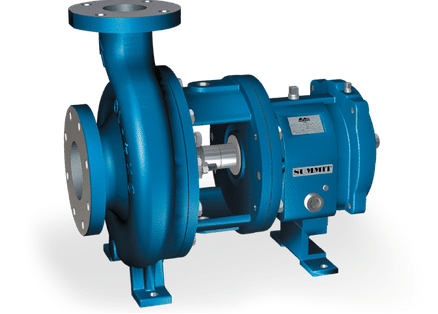

Centrifugal pumps are mechanical devices used to move liquids. This type of pump has been around since 1689 and has been adapted for use in a variety of industries. Centrifugal pumps are often used to pump water, solvents, acids, and other materials in industrial, manufacturing, agricultural, and domestic applications.

Why You Should Focus on Centrifugal Pump Efficiency

If your centrifugal pumps aren’t efficient, your business is leaving a lot of money and productivity on the table. According to a U.S. Department of Energy analysis, centrifugal pumps are the largest consumers of motor energy in plants. That also means they have the greatest potential for energy savings.

Another Finnish Research Center study of centrifugal pump performance revealed that the average pump efficiency was less than 40%, and some pumps were even operating at only 10% efficiency. By optimizing your existing centrifugal pumps, you can save money and maximize your operation’s output.

How to Increase Centrifugal Pump Efficiency

Believe it or not, pumps account for roughly 10% of global energy consumption, and much of the energy consumed isn’t efficient. If you consider the benefits of having a pump operating at maximum efficiency, it makes sense to have this as one of your priorities. Here are some of the ways you can increase centrifugal pump efficiency.

1. Avoid Oversized Pumps

One of the most common culprits of pump inefficiency is the use of oversized pumps. A pump is considered “too big” if it is operating outside 20% of its Best Efficiency Point (BEP) on the pump curve. But, it’s an acceptable size if the pump’s duty point is between 50% and 100% of the BEP flow rate.

Larger pumps require more energy to operate, leading to unnecessary costs. While a certain margin of error is acceptable and even recommended to account for growth and demand fluctuations, it’s a good idea to stay as close to your BEP as possible to conserve energy.

2. Trim Pump Impellers

If you find out that your centrifugal pump is oversized, you can reduce the pressure and flow by sizing down the impellers. When you trim your impellers, this can make your pump more energy efficient. Impeller trimming reduces the top speed of the pump, which also lowers the pump’s pressure and flow rate. Another alternative is to replace your current impellers with smaller ones.

3. Use Variable Frequency Drives (VFDs)

VFDs allow a centrifugal pump to operate near its BEP at any flow or head by varying the motor’s rotational speed to match the actual flow and head demand of the application instead of simply what the pump can generate.

Using a VFD is more efficient because it can eliminate unnecessary energy consumption. For example, a VFD used in the wastewater and water industry can reduce power consumption by up to 75%.

4. Pumps in Parallel

Using multiple pumps instead of just one is another strategy that can improve efficiency and lower energy consumption. When you install a second pump that runs in parallel to your primary centrifugal pump, it can take some of the excess load off of your overall system. Also, if one pump fails or requires maintenance, you still have another pump available to continue operations.

5. Optimize Piping

It’s always better to spend time optimizing your piping during the design phase of initial pump installation, but that doesn’t mean you can’t make some changes to gain more efficiency after the fact. You can reduce pressure drops by minimizing sudden changes in pipe sizes and sharp bends in your piping. You can also reduce friction loss by using higher quality piping and low loss fittings and valves.

6. No Unnecessary Use

Some pumps may operate unnecessarily, which consumes more energy than is needed. You can install a control system that allows you to monitor and control the pump remotely. Depending on the requirements at any given time, you will be able to stop and start the pump, giving you more efficient results.

7. Review the Motor

Similar to using oversized pumps, a motor that is too powerful for your needs can make your system inefficient. While it makes sense to choose a motor slightly larger than your current needs to accommodate an increase in capacity, you don’t want to go overboard. Getting a high-efficiency motor for your centrifugal pump is the best option.

8. Conduct Regular Maintenance

Pump wear can account for as much as 25% of your centrifugal pump’s reduction in efficiency. Signs of wear include greater clearance between fixed and moving parts, cavitation, and wear in bearings and rings.

Proper maintenance and upkeep can improve your pump’s efficiency and extend its useful life. This includes things like bearing inspection, lubrication, and replacement, impeller inspection and replacement, wear ring replacement, mechanical seal inspection and repacking, and motor/pump alignment check.

C&B Equipment Sells and Services Centrifugal Pumps

If your business wants to get the most out of its centrifugal pump or would like to purchase a new one, C&B Equipment can help. We sell and service all types of centrifugal pumps to clients throughout the Midwest.

We are an industrial distribution and service company that focuses on helping clients maximize uptime with the most reliable and efficient solutions. We carry a full line of centrifugal pumps and assist clients with service, maintenance, and repair.

Contact us today to find out more about how we can help your business.