Types of Centrifugal Pumps: Which is Right for Your Facility?

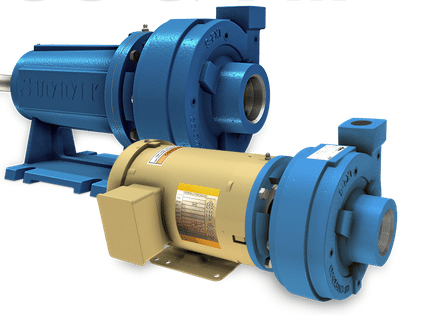

Centrifugal pumps are the most common type of pump used today. That being said, there are a seemingly endless number of ways to configure centrifugal pumps to meet the needs of almost any industry or application.

Determining the right type of pump for your facility depends on what you’re pumping, the pressure in which you’re pumping it, the direction in which you’re pumping it, and how you’re pumping it. Additionally, your application may have specific requirements for the type of pump you need to use.

What Is a Centrifugal Pump?

Facilities use centrifugal pumps to transfer liquids. As you may have guessed, centrifugal pumps generate centrifugal force to transfer liquids through the pump.

Centrifugal pumps are typically easy to operate, have a relatively low purchase price, and fewer maintenance costs. In addition, centrifugal pumps are fairly quiet. They also have fewer moving parts, adding to their durability and ease of maintenance.

What Types of Centrifugal Pumps Exist?

With a wide variety of centrifugal pumps available from many manufacturers, you will need to consider specific pump characteristics and application requirements when selecting the right pump for your facility. Commonly, centrifugal pump manufacturers define the stage, split case, suction type, shaft orientation, and industry-standard specifications.

Stage

The stage defines the number of impellers within a centrifugal pump.

- Single-stage. Featuring a single impeller, single-stage pumps offer a simple, affordable design and easy maintenance. Single-stage pumps typically handle large flow rates and are used in low-pressure applications.

- Two-stage. Two-stage centrifugal pumps feature two impellers for more advanced, medium-pressure applications.

- Multi-stage. These advanced centrifugal pumps feature three or more impellers and are used primarily for high-pressure applications.

Split case

The split case construction characteristic determines how the centrifugal pump develops pressure.

- Axial. The impeller creates pressure by pushing liquid parallel to the pump shaft

- Radial. The impeller creates pressure by pushing the liquid perpendicular to the pump shaft.

Suction type

For centrifugal pumps, suction type determines how fluid enters the impeller blades through the pump.

- Single suction. Fluid enters through one side of the impeller blades.

- Double suction. Fluid enters through both sides of the impeller blades.

Shaft orientation

A centrifugal pump’s shaft orientation defines the direction of the shaft within the pump.

- Horizontal. Easy to install and maintain, these pumps feature a horizontally positioned shaft.

- Vertical. Vertical pumps have their shaft in the vertical plane. They utilize a unique shaft and bearing support configuration. These are well suited for direct coupling to an electric motor.

Standard Specifications

Depending on your facility and application, your centrifugal pump may need to meet standard specifications for use.

- ANSI. Meets the standards of the American Society of Mechanical Engineers. This certification ensures the pump is interchangeable with other ANSI pumps of similar size. See Why You Should Consider and ANSI Centrifugal Pump to Improve Efficiency for more information.

- API. Meets the standards of the American Petroleum Institute. These pumps meet specific standards in regards to handling the high pressure and temperature demands of the petroleum industry.

- DIN. Meets DIN specifications for use with large flow rates, extremely high pressures or extremely high temperatures.

- ISO. Meets International Standard requirements for centrifugal pumps.

- Nuclear. Meets the American Society of Mechanical Engineers specifications for use in nuclear applications.

What Types of Applications Use Centrifugal Pumps?

Centrifugal pumps are used by a wide variety of industries for various processes. These include agriculture, chemical processing, municipal and industrial wastewater management, oil and gas, food processing, pulp and paper processing, manufacturing, solids handling, high temperature, ethanol management, and biodiesel management.

Too Many Options? C&B Equipment Can Help

Do you have questions about choosing the right centrifugal pump for your facility? The pump experts at C&B Equipment can help you determine the proper centrifugal pump for your facility, based on your business’s specific needs.

To learn more about the centrifugal pump options offered by C&B Equipment, contact us today at 1-800-362-3222 or fill out a contact form, and we’ll be in touch.