What Are Liquid-Ring Vacuum Pumps?

Liquid-ring vacuum pumps are rotating positive displacement industrial pumps that use vacuums to pump fluids in rigorous industrial applications. Several industries, including the chemical, pharmaceutical, environmental, food and beverage, oil and gas, mining, and marine industries, utilize liquid-ring vacuum pumps to accomplish daily tasks.

Liquid-ring vacuum pumps are rotating positive displacement industrial pumps that use vacuums to pump fluids in rigorous industrial applications. Several industries, including the chemical, pharmaceutical, environmental, food and beverage, oil and gas, mining, and marine industries, utilize liquid-ring vacuum pumps to accomplish daily tasks.

Liquid-ring vacuum pumps use water and other liquids as a sealant. Liquid-ring vacuum pumps are a safe and reliable way to handle dirty and potentially dangerous gas streams because their parts do not come into contact with each other. They are available in single-stage and dual-stage formats, and manufacturers can configure them as compressors to give them increased versatility.

5 Benefits of Liquid-Ring Vacuum Pumps

Liquid-ring vacuum pumps can benefit you and your operation in several ways, including the following.

- They are not affected by carryover

- They operate quietly and at cool temperatures

- They operate consistently

- They last a long time and require little maintenance

- They are better for the environment

1. They Are Not Affected by Carryover

Carryover, such as soft solids, moisture, slugs, and chemicals, will not affect a liquid-ring vacuum pump’s performance or harm it in any way. The pump will dispel these unwanted bodies and impurities via its discharge ports.

2. They Operate Quietly and at Cool Temperatures

Liquid-ring vacuum pumps are relatively quiet compared to other industrial equipment; the noise they make seldom exceeds 85 decibels. The circulation of the sealing liquid inside the pumps keeps them running at cool temperatures.

3. They Operate Consistently

Liquid-ring vacuum pumps will operate constantly and consistently at any vacuum level, making them ideal for precise applications.

4. They Last a Long Time and Require Little Maintenance

Liquid-ring vacuum pumps have a single moving part: the rotor. The fewer moving parts a piece of equipment has, the less likely it is that things will break. Liquid-ring vacuum pumps require far less maintenance than other types of industrial equipment that feature multiple moving parts. Their robust and sturdy design makes them ideal for rough conditions and rigorous tasks.

5. They Are Better for the Environment

Liquid-ring vacuum pumps are oil-free, meaning your industrial plant will be cleaner, and you won’t have to worry about oil contamination and discharge.

Elmo Rietschle Liquid-Ring Vacuum Pumps

Liquid-ring vacuum pumps are constantly exposed to humid and wet conditions. These conditions can cause limescale and abrasion, degrading your pump’s components and considerably diminishing your pump’s performance and output. You need a pump that is not only of the highest quality but also specifically designed to withstand these conditions. An Elmo Rietschle liquid-ring vacuum pump is precisely what you need.

Elmo Rietschle is part of Gardner Denver, a leading global manufacturer of highly engineered products. Elmo Rietschle specializes in manufacturing liquid-ring vacuum pumps and compressors designed to meet the challenges of extreme environments and exceed industry standards.

Elmo Rietschle uses ceramic coatings and high-quality materials, such as stainless steel, that provide excellent abrasion and corrosion resistance. If you use Elmo Rietschle liquid-ring vacuum systems, you will never have to worry about deposits or limescale affecting your equipment’s integrity. These pumps are reliable and consistent, ensuring your operations run smoothly for years to come.

Liquid-Ring Vacuum Pumps for Any Application

C&B Equipment offers several state-of-the-art Elmo Rietschle liquid-ring vacuum pumps, including the following.

- L-BV2 Liquid-Ring Vacuum Pump

- L-BV5 Liquid-Ring Vacuum Pump

- L-BV7 Liquid-Ring Vacuum Pump

- L-BL2 Liquid-Ring Vacuum Pump

L-BV2 Liquid-Ring Vacuum Pump

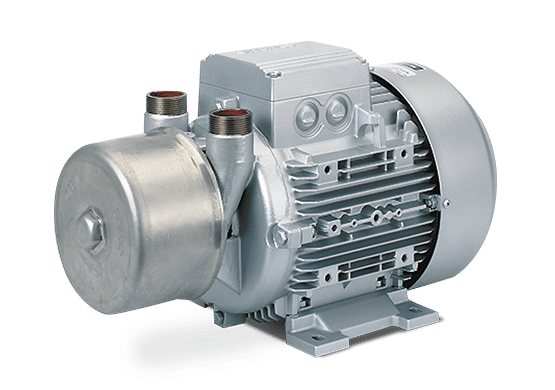

This robust and reliable pump features monoblock construction, making it ideal for use in the plastic and medical industries. It is available in a variety of materials to cater to multiple applications. The L-BV2 is customizable and offers long-term resistance to erosion and corrosion. It provides a volume flow of anywhere from 15.9 to 85.3 cubic feet per minute (CFM), and roller bearings with additional lubricant reservoirs provide safe and maintenance-free operation, even under the heaviest loads.

L-BV5 Liquid Ring Vacuum Pump

Thanks to its ceramic coating and reinforced stainless steel shafts, this extremely quiet pump lasts a long time. It provides a suction pressure of up to 33 millibars (mbar) and a volume flow of anywhere from 52.9 to 352.9 CFM. We also offer a specialized model of the L-BV5 that has a pump body made entirely of stainless steel, and we can outfit it with IE2 motors upon request.

L-BV7 Liquid Ring Vacuum Pump

The L-BV7 is also an extremely quiet liquid ring pump. It is completely covered with stainless steel, and it provides up to 50% less water consumption and an inlet pressure of up to 33 mbar. Its ceramic coating and reinforced stainless steel shafts help it last a long time. We can also outfit it with IE3/Nema Premium motors upon request.

L-BL2 Liquid Ring Vacuum Pump

The L-BL2 provides users with a compact plug-and-play system for easy on-site installation. Thanks to its contact-free compression, it’s nearly 100% wear-free and does not require periodic maintenance. It is also oil-free and does not require additional water during operation.

Elmo Rietschle also offers a compact version of the L-BL2 called the “pump in the box.” These portable units are oil-free and air-cooled. They include an L-BV liquid ring pump, an industrial electric motor, a discharge separator, a seal liquid cooler, and a discharge air cooler.

Get Your Elmo Rietschle Liquid-Ring Vacuum Pump from C&B Equipment!

C&B Equipment is proud to be a licensed distributor of Gardner Denver industrial pumps, including its Elmo Rietschle liquid-ring vacuum pump line. The efficient, consistent, durable, and reliable nature of liquid-ring vacuum pumps will get the job done correctly and minimize your unplanned downtime—that’s the mission that guides everything we do.

Reach out to C&B Equipment for help choosing the right type of pump for your application. We also offer preventative maintenance and repair services to ensure your equipment runs at peak performance 100% of the time!