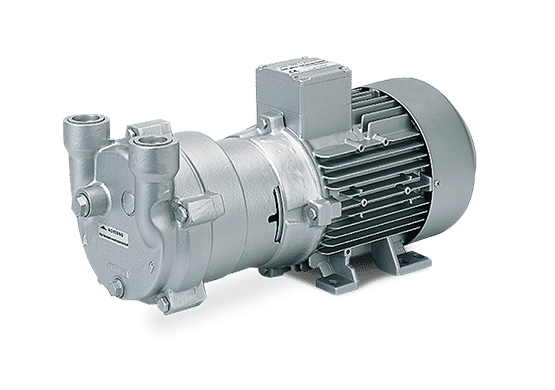

A Look at Liquid Ring Vacuum Pump Design and Why It Is Important

Have you been considering a liquid ring vacuum pump for your business?

Built with environmental safety, durability and long-time run capacities in mind, liquid ring vacuum pumps help businesses in just about any industry with a variety of applications and have the ability to stand up to extreme conditions.

Liquid ring vacuum pumps are unique, in that they use a process compatible liquid, such as water, as a sealant during the compression process.

Uses for Liquid Ring Vacuum Pumps

Companies and manufacturers alike can use liquid ring vacuum pumps for many gas transportation needs.

Benefiting from the careful compressor design of the pump, they can safely and reliably compress, evacuate, or transport dirty and potentially dangerous gases with minimal risk.

Liquid ring vacuum pumps utilize water, or in some cases oil, as the sealing media to transport gases through the pump. Since liquid ring vacuum pumps have very few internal parts that make no contact during the transportation process, they are inherently durable and long-lasting, even with continuous use.

How Are Liquid Ring Vacuum Pumps Designed?

Liquid ring vacuum pumps transport gases using a single moving part, the rotor. Additionally, a center cone directs gases by providing a gas inlet port and discharge port for compressing, evacuating, or transferring gases through the pump’s compressor. Both the rotor and cone are housed within the pump’s casing.

Additional parts, including the liquid ring vacuum pump’s motor and bearings, are located outside of the main pump’s casing. This design allows for easy maintenance and repair. This also helps minimize risk when working with dangerous gasses.

How Does it Work?

The design behind liquid ring vacuum pumps allows them to seamlessly operate using the following process:

- The motor begins spinning an offset rotor within the compressor.

- As the rotor spins, a liquid ring forms following the inner contour of the compressor’s body.

- The spinning liquid forms a seal within the compressor, creating a vacuum within the compressor chamber. The rotor is offset in the compressor chamber, allowing the liquid to recede from, then reenter the chambers between the rotor blades with every revolution. This creates an effect similar to a piston forcing air into the chamber between the rotor cylinder.

- As the liquid recedes from the rotor’s chambers gas begins to enter the compressor through the cone’s inlet port.

- As the rotor spins a chamber to the top of the pump, the liquid forming the sealant begins to reenter the chamber, compressing the gas through the cone’s discharge port.

- The gas exits the compressor through the discharge port.

Benefits of Using a Liquid Ring Vacuum Pump

Liquid ring vacuum pumps are often used by the chemical, electrical power, environmental, food and beverage, marine, mining, oil and gas, pharmaceutical, pulp and paper, and textile industries for the following reasons:

- Sound. With minimal contact-based parts in operation, most pumps operate below 85 dba.

- Temperature. Using a liquid as a sealant, liquid ring vacuum pumps offer cooler operational temperatures.

- Durability. Since liquid ring vacuum pumps have fewer moving parts that make contact with one another, they typically have lower maintenance costs and longer lifespans.

- Environmental impact. Water-based liquid ring vacuum pumps can run without oil as a lubricant or sealant within the compressor, minimizing the risk of unintentional environmental pollution or contamination.

Want to Learn More?

The pump experts at C&B Equipment can help you find the perfect vacuum pump for your business. We specialize in Uptime Solutioneering, increasing your business’s mean time between system failures and improving efficiency.

Click here to learn more about our available liquid ring vacuum pumps. You can also give us a call! Our Wichita, KS team can be reached at 316-262-5156 or call our Lenexa, KS crew at 913-438-1212.