Your Guide to ANSI Process Pumps

Centrifugal ANSI process pumps are a dependable workhorse for many operations and applications. Regulated by the American National Standards Institute (ANSI), these particular pumps have to meet specific dimensional standards. With strict regulations, it’s easy to interchange pumps when one breaks down; however, ANSI process pumps do have their limitations.

We’ve put together this quick guide to help you understand the pros and cons of ANSI process pumps, the applications they’re best suited for and the specific pumps we recommend.

What Are ANSI Process Pumps?

ANSI Process pumps are a dimensionally regulated type of centrifugal pump. These pumps are horizontal, end suction, single-stage pumps. All ANSI process pumps are similar in size and identical in interface. With these regulations in place, it’s easy to swap out pumps as needed.

While the sizes and interfaces are specifically defined, there are many ANSI process pump features that vary by manufacturer. For example, some ANSI process pumps can be manufactured using specific materials to handle corrosive liquids.

There are three main groups of ANSI process pump, based on size:

- Group I. Sizes from 1.5 by 1-6 to 3.0 by 1.5-8

- Group II. Sizes from 3 by 2-8 to 6 by 4-13

- Group III. Sizes from 6 by 4-16 to 10 by 8-17

Applications for ANSI Process Pumps

Typically, ANSI process pumps are used for applications that require transferring water and thin liquids. Centrifugal pumps are usually not the best choice for thicker liquids and oils. Likewise, some ANSI process pumps are capable of pumping liquids containing solids. Be sure to verify with an expert or manufacturer before purchasing an ANSI process pump to be sure it’s compatible with your operation.

ANSI process pumps only meet one standard and may not be the best choice for all centrifugal pump applications. If you’re unsure when choosing an ANSI process pump for your application, our pump experts can make a recommendation for you.

The chemical industry is the primary user of ANSI process pumps. Additionally, food processing, paper mills, pulp mills, refineries, ethanol production, textiles and various other process plant applications depend on these pumps.

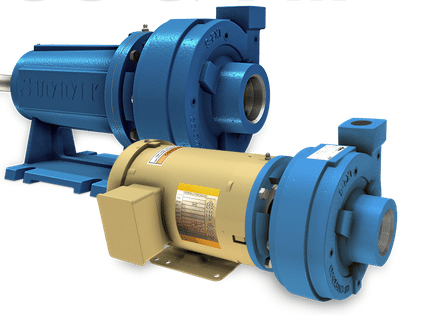

ANSI Pumps Offered by C&B Equipment

At C&B Equipment, dependability and reliability are essential for the pumps that we sell. There are plenty of ANSI process pumps on the market—we’ve chosen the pumps we sell based on our experience in helping operations stay up and running.

Summit 2196 ANSI

The Summit 2196 ANSI centrifugal process pump features a rear pull-out design and efficient, interchangeable parts. These pumps can handle capacities up to 600 GPM, heads up to 730 feet, and temperature up to 700 degrees Fahrenheit.

Dean Pump pH Series Horizontal ANSI

The Dean Pump pH Series Horizontal ANSI pump is available in 28 different sizes with integral one-piece casing flanges and a fully open propeller. This medium duty pump can handle capacities up to 3,200 GPM, heads up to 800 feet and pumping temperatures up to 500 degrees Fahrenheit.

Summit Clark 3

The Summit Clark 3 is a general purpose pump, which features a rear pull-out design, threaded bearing housing and a reverse vane closed impeller. This pump can handle capacities up to 5,000 GPM and heads up to 740 feet.

Grundfos CR(N)-H

The Grundfos CR(N)-H ANSI process pump promises maximized pump efficiency and minimal internal wear with a significant reduction in energy costs, maintenance efforts and downtime. With a high corrosion resistance, Grundfos has manufactured this pump to handle capacities to 210 GPM, heads to 630 feet, and liquid temps from -22 degrees Fahrenheit to 248 degrees Fahrenheit.

C&B Equipment, We’re Your ANSI Process Pump Experts

The ANSI standard makes it easy to replace and swap out these specific process pumps. However, not all pumps are manufactured the same. We know how crowded the ANSI process pump market is. As a consumer, it can be difficult to determine the best pump for your application—that’s where we come in.

With our experience installing, maintaining and repairing ANSI process pumps, we can help you make an informed decision when buying a new ANSI process pump for your operation. Contact us today to learn more.