C&B Equipment’s Ultimate Guide to Industrial Water Pumps

Industrial water pumps are used in a variety of industries. They come in several different types, shapes, sizes, and configurations, all of which are catered to different environments and pumping requirements. Industrial water pumps have many advanced features designed for the unique demands of different industries and businesses.

However, it can be difficult to know exactly the type of pump that you need or what sort of pump suits the environment you work in. This guide to industrial water pumps can help you. We are going to answer some of the common questions that you may have and give you an overview of the types of water pumps available on the market.

What Are the Applications of Industrial Water Pumps?

Industrial water pumps are typically used for two reasons: removing excess water from a location or pumping a large volume of water into a specific area. One of the most common applications of water pumps is the removal of floodwater from a location that does not have the proper drainage to dispose of the water.

For example, if heavy rainfall occurs at a construction site, then the operation may have to be put on hold due to flooding and equipment damage. An industrial water pump can help to remove the water and get the operation back on track much more quickly.

Other common applications for industrial water pumps include the following.

- Water and Wastewater Treatment

- Cooling and Heating

- Washing and Cleaning

- Fire Protection

- Wastewater Transport

What Are the Different Types of Industrial Water Pumps?

Industrial water pumps can generally be placed into two categories: centrifugal pumps and positive displacement pumps.

Centrifugal Pumps

Centrifugal industrial water pumps are the most commonly used pumps and are found in a variety of industries. They are usually cost-effective, and their simplistic design requires very few moving parts. These types of pumps are designed to be consistent and typically don’t require much in the way of maintenance.

Centrifugal pumps utilize a rotating impeller that draws water into the pump, where centrifugal force pressurizes the water for discharge. Centrifugal pumps need to be primed before use. Thus, they perform well when submerged under water or when situated below the level of the input source.

Different varieties of centrifugal pumps include the following.

- Booster pumps

- Fire pumps

- Grinder pumps

- Trash pumps

- Vertical turbine pumps

Centrifugal pumps are the ideal choice for high flow rates, as they don’t suffer from the pulsations that may occur in a positive displacement pump.

Positive Displacement Pumps

Unlike centrifugal pumps, positive displacement pumps do not utilize an impeller. They use rotating or reciprocating parts to move water along and build up pressure for when it is ready to be discharged.

Different varieties of positive displacement pumps include the following.

- Metering pumps

- Plunger pumps

- Piston pumps

- Peristaltic pumps

Positive displacement pumps are perfect for applications that require a lower flow rate, a high pressure, or a combination of both.

How Do I Know Which Type of Pump I Need?

When choosing an industrial water pump, it is important that you understand the advantages and disadvantages of each one. Certain industrial water pumps are more effective for residential properties, whereas others are more effective for commercial properties and industrial purposes. Take this into consideration when choosing which one is right for you.

Depending on the amount of water you will be transporting, you may need to invest in a more heavy-duty pump. Some pumps are more equipped to deal with a high pressure and have a much higher flow rate than others. As mentioned before, centrifugal pumps can pump water much more quickly than the positive replacement variety.

The best way to determine which pump is correct for you is to contact and discuss with a reliable supplier. C&B Equipment has a highly experienced team of designers, engineers, fabricators and technicians to help you achieve the most affordable and effective solutions. Take a look at all of the services that we provide!

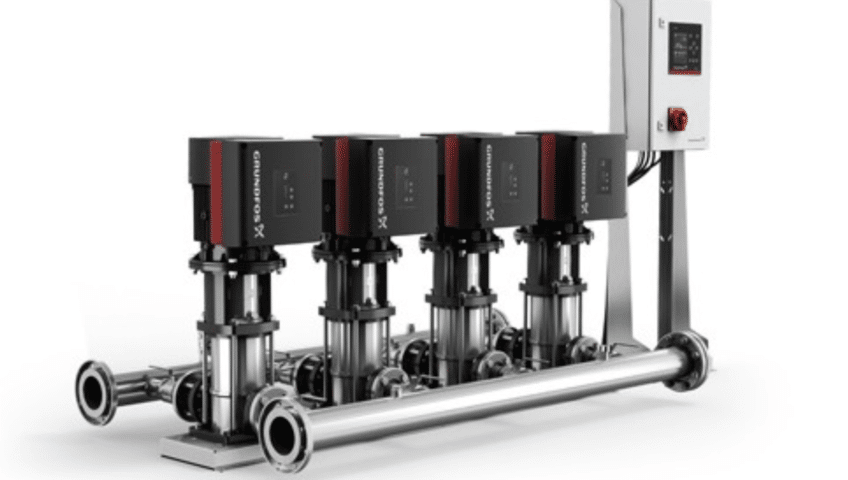

Introducing Grundfos’s New, State-of-the-Art Line of CR Industrial Water Pumps

These pumps set the standard in terms of innovation, efficiency, reliability and sustainability. The new generation of CR vertical inline multistage pumps bring even greater efficiency, reliability and ease of use to more applications than ever before. Read this case study to see how the new CRs saved one chemical plant $30,000 per year!

Because of their ability to handle more than 1,000 GPM and 1,000 feet of head, this CR technology is equipped to deal with intensive tasks like pressure boosting, reverse osmosis, water transfer, and temperature control. Its state-of-the-art technology brings you greater reliability:

- Enhanced impeller and chamber design that reduces NPSHr

- Low vibration that reduces noise and wear and tear

- Balance radial loads prevent the shaft deflection that’s common in single-stage pumps

- New thrust handling device allows use of standard motors

…easier serviceability:

- The cartridge mechanical seal can be replaced in minutes without removing the motor

- Rotating assembly stacking kit allows for easy replacement

- No need to realign or rebalance the pump

…and higher efficiency:

- Best Efficiency Point (BEP) as high as 81%

- Higher efficiency across a broader range of points on the curve

- Improved impeller design reduces energy loss

- Optimized flow path reduces pressure loss

The newest line of CR industrial water pumps can be customized in millions of different ways to suit an infinite number of applications including drinking water treatment, wastewater transport, agriculture, irrigation, rainwater harvesting, and much more. These heavy-duty pumps can handle whatever task is thrown at them.

C&B Equipment Is Here to Help You!

C&B Equipment distributes a wide range of industrial equipment, including industrial pumps and vacuum systems, blowers, motors, and mechanical seals. We understand that every minute of downtime can negatively affect your business, so we offer a variety of emergency services including preventative maintenance programs, equipment repair and rebuilds, and pump base installation.