C&B Equipment’s Complete Guide to Multistage Centrifugal and Positive Displacement Blowers

There are many different types of industrial blowers, chief among them being multistage centrifugal blowers and positive displacement blowers. This blog post will explain everything you need to know about each type of blower, including their purposes and the differences between them so that you can make the most informed choice.

What Is a Multistage Centrifugal Blower?

A multistage centrifugal blower is designed to move air or other gasses and operates on the principle of centrifugal force, which involves rapidly spinning impellers (rotors) to increase the velocity of the air. The air is then pushed outwards by the centrifugal force created by the rotating impellers. This process occurs in multiple stages, each increasing the pressure of the air by a certain amount, and the multistage design allows these blowers to handle high-pressure differentials and high flow rate applications, making them ideal for certain industrial processes.

How a Multistage Centrifugal Blower Works?

As air enters the center of a rotating impeller, it imparts kinetic energy to the air, causing it to move radially outwards due to the centrifugal force. This radial movement of air through the impeller increases its velocity. After leaving the impeller, the high-speed air enters a diffuser, where the velocity of the air is converted into pressure due to the diffuser’s divergent design.

This process is repeated in each subsequent stage or impeller of the blower. The air or gas is propelled from one stage to another, each time gaining velocity and being converted into pressure. The result is a high-pressure output suitable for heavy-duty industrial applications.

The number of stages or impellers a blower has is reflective of its capacity to increase the pressure of the air or gas. More stages result in higher pressure differentials, making multistage centrifugal blowers versatile and capable of handling varied industrial process requirements.

Types of Multistage Centrifugal Blowers

There are several types of multistage centrifugal blowers, each designed to cater to specific industrial needs.

Low-Pressure Multistage Centrifugal Blowers: These blowers are designed to operate under lower pressure conditions and are typically used in applications such as wastewater treatment, air conditioning, and combustion air supply.

High-Pressure Multistage Centrifugal Blowers: These blowers are constructed to withstand high-pressure differentials and are often employed in power generation, oil and gas industries, and other heavy-duty applications.

Variable Speed Multistage Centrifugal Blowers: These blowers offer the advantage of speed control, allowing them to adapt to varying process conditions. This makes them suitable for applications that require flexible operating conditions.

Multistage Centrifugal Blowers with Heat Exchangers: These blowers come equipped with heat exchangers that help in cooling the air/gas during the compression process. This feature is critical for applications where high-temperature operation could damage the system or affect the process quality.

Uses for Multistage Centrifugal Blowers

Multistage centrifugal blowers, due to their versatile nature, are employed across a diverse range of industries for various applications:

Automotive: They are integral to automotive cooling systems, helping to dissipate heat and maintain optimum engine performance.

Medical: In medical facilities, multistage centrifugal blowers play a critical role in creating sterile environments, helping to prevent the spread of pathogens.

Mining: In the mining industry, these blowers are used for ventilation, dust extraction, and cooling of machinery.

Agriculture: They assist in grain aeration, helping preserve the quality of stored grain and prevent spoilage.

What is a Positive Displacement Blower?

A positive displacement blower, also known as a PD blower or rotary air blower, is a type of machine that is used to move gas or air for a variety of applications. This blower operates by trapping a specific volume of air and then discharging or forcing it out against the system pressure. This cyclical process occurs in a constant and steady flow, making PD blowers incredibly efficient for a multitude of uses, particularly in industries requiring high-volume and high-pressure air movement.

How a Positive Displacement Blower Works

A positive displacement blower operates on a simple mechanism: it captures air in a particular volume and then discharges or forces out the air against the system pressure. The process begins as the air enters the inlet of the blower.

The rotary lobes, typically in a figure-eight configuration, spin in opposite directions. As they rotate, they trap a fixed amount of air at the inlet. This air gets confined within the casing and the lobes and is then transported to the outlet side.

The rotating lobes then direct the air from the intake side to the discharge side. As the air reaches the discharge side, the lobes disengage, releasing the air at nearly the same pressure as when it was trapped. The cycle then repeats.

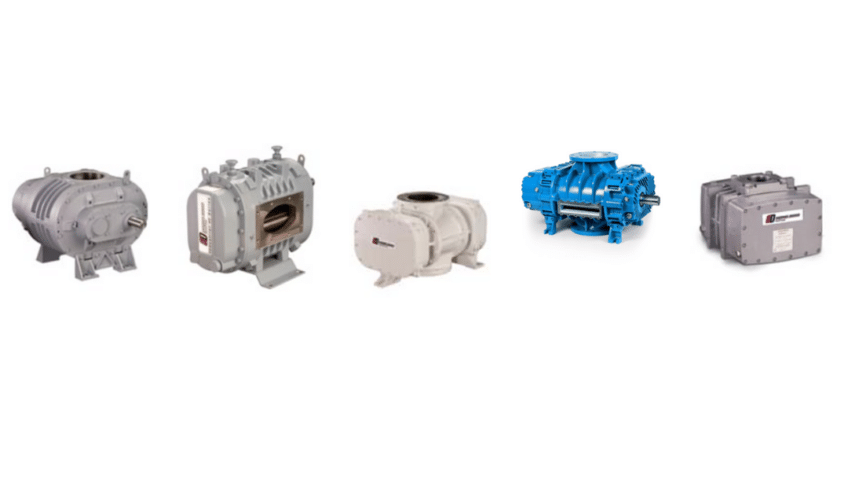

Types of Positive Displacement Blowers

Typically, two types of positive displacement blowers are characterized by their construction.

Rotary Vane Blowers: This type of blower has a round rotary that rotates within a circular cavity. There is an offset between the centers of the two circles, which creates energy within that space.

Rotary Lobe Blowers: Also called a “roots blower,” rotary lobe blowers have two impellers in a figure eight shape that rotate in opposite directions, causing the blower to trap air or gas in the desired location.

Uses for Positive Displacement Blowers

Positive displacement blowers are pivotal in various industries due to their wide-ranging applications:

Water Treatment: They are extensively used for aeration in sewage and wastewater treatment plants. The blowers inject air that helps bacteria break down organic matter effectively.

Food and Beverage Industry: In the food and beverage industry, they play a critical role in pneumatic conveying systems that transport food materials, ensuring hygienic and efficient operations.

Chemical Industry: In the chemical industry, these blowers are employed for gas boosting and for handling a variety of gasses in the production process.

Agriculture: Blowers are used in agricultural processes such as venting, aeration, and drying of agricultural products. Positive displacement blowers are also used to extract and properly manage methane, which helps to reduce emissions and promote environmental sustainability in agricultural operations.

Get the Right Industrial Blower for Your Needs

If your business needs an industrial blower, choosing the right one can be challenging. There are a lot of factors to consider, and you don’t want to make the wrong choice when purchasing a large piece of equipment. C&B Equipment can help.

We are an industrial equipment distribution and service company for blowers, pumps, air compressors, and related equipment. Our company provides factory-engineered packages built to specifications and engineering, repair, and field service support designed to keep your operations running at peak efficiency.

We service clients throughout Kansas, Missouri, Arkansas, and the Texas Panhandle. Contact us today to learn more about how we can help with your industrial equipment needs!