7 Common Causes of O-Ring Failure

O-ring seals are some of the most common seals used in machine design. They prevent the loss of fluid and gas and are incredibly inexpensive, easy to make, reliable, and have simple mounting requirements.

O-ring seals are some of the most common seals used in machine design. They prevent the loss of fluid and gas and are incredibly inexpensive, easy to make, reliable, and have simple mounting requirements.

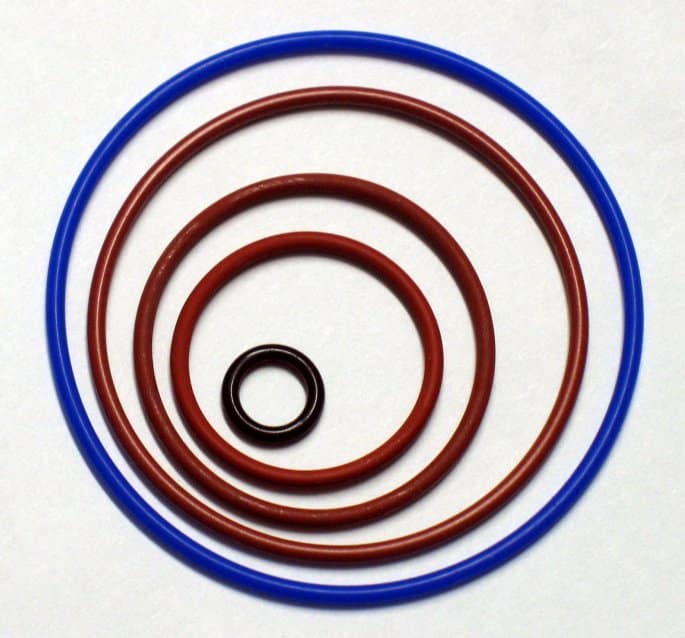

Although O-rings are designed to be seated in a groove and compressed between two or more parts, they vary drastically in cross-sectional shape, color, hardness (durometer), and curing method.

Every manufacturer designs its O-rings to solve a specific problem for a particular application, so you must select your O-rings based on their functionality and your requirements.

With so many brands, shapes, and sizes to choose from, it can be challenging to determine the best fit for you. Thankfully, C&B Equipment has the extensive knowledge and practical experience to ensure your O-rings are nothing short of… well, boring. Let’s face it. If your O-rings aren’t boring, then they are likely causing problems.

The following are common causes of O-ring failure. This troubleshooting guide will help you identify issues with your O-rings, explain what is causing those issues, and help you prevent similar problems in the future.

1. Compression Set

What Is it and What Causes It?

Compression set occurs when an O-ring becomes squashed into a flat-sided oval. It won’t recover after removing the stressor, and it has permanently “set” into the deformed shape. Compression set is one of the most common causes of O-ring failure.

The following are common causes of compression set.

- Using an O-ring material with poor compression set properties

- Embrittlement at high temperatures causes the O-ring to lose its elasticity and ability to return to its original shape

- Volume swell

- Contact with fluid incompatible with the O-ring material

- Improper gland design

- Incomplete curing during production

What Are Some Ways to Prevent It?

Use an O-ring material with low compression set and high temperature resistance. Check the gland design to make sure the O-ring isn’t over-compressed. Reduce the system’s operational temperature if needed and alleviate excessive frictional heat build-up at the seal face.

2. Extrusion and Nibbling

What Is it and What Causes It?

Extrusion occurs when high stresses force the O-ring material into the clearance gap between the mating flanges. Pulses of high pressure cause the clearance gap to open and close, trapping the O-ring between the sharp edges. This causes physical damage called “nibbling.”

The edges of the O-ring on the low-pressure side will have a chipped, chewed, or frilly appearance. Extrusion and nibbling usually occur in dynamic applications like hydraulic rods and piston seals.

High pressure above system design and tolerances and excessive or irregular clearance gaps are common extrusion causes. The O-ring material may be too soft, or the O-ring installed too large.

What Are Some Ways to Prevent It?

Reduce machining tolerances to decrease clearance. Ensure installation of correctly sized O-rings and try a more rigid material if necessary. Use backup devices to reduce clearance gaps. In some cases of extrusion and nibbling, O-ring size and shape are the problems.

For sealing applications with unusual geometries, custom-made O-rings, such as those offered by Kalrez®, may be an appropriate solution.

3. Abrasion

What Is it and What Causes It?

Abrasion occurs when there is repetitive contact between the O-ring surface and the housing. The excessive friction wears down the sliding contact faces of the O-ring, resulting in wear lines or even deep scratches and breaks.

The surface may look dull or glazed, and one side of the O-ring will be worn flat. Abrasion is typical in dynamic applications that involve rotary, oscillating, or reciprocating motion.

Inadequate lubrication, improper surface finish on metalwork, abrasive particles in the system fluid, and excessive temperatures can cause abrasion.

What Are Some Ways to Prevent It?

Ensure adequate lubrication and the correct surface finish on metalwork. Check the system fluid for contaminants and install filters or wiper/scraper rings if needed. Consider swapping to internally lubricated O-rings or an O-ring material with higher abrasion resistance.

4. Explosive Decompression

What Is it and What Causes It?

Explosive decompression, also referred to as gas expansion rupture, occurs when high-pressure gas becomes trapped within the internal structure of an elastomer seal.

When exposed to high-pressure gas at high temperatures for an extended time, the O-ring’s polymer compound may absorb the gas. When the system pressure drops, the trapped gas expands to match the external pressure, causing surface cracks and blisters as the gas escapes.

Small amounts of gas may have little effect on your seal’s integrity, as the blisters may recede after the pressure equalizes. However, excessive amounts of trapped gas may cause severe damage or even rupture the O-ring.

What Are Some Ways to Prevent It?

Increase time for decompression and reduce system temperature. Choose an O-ring material resistant to explosive decompression or use an O-ring with a smaller cross-sectional size.

5. Chemical Degradation

What Is it and What Causes It?

Many chemicals will react to certain O-ring materials. Degradation occurs when the O-ring material is unable to withstand the effects of a particular chemical. Elevated temperatures, excessive stretch or compression, and mechanical stresses can accelerate chemical attacks.

A degraded O-ring may show discoloration, blistering, cracking, or a change in shape or hardness. The specific indications vary by chemical reaction.

What Are Some Ways to Prevent It?

Choosing a suitable O-ring material is key to preventing chemical degradation. For the best chemical resistance in high temperatures, the gold standard is perfluoroelastomer (FFKM) material. Kalrez® FFKM O-rings resist attack from more than 1,800 chemicals, solvents, and plasmas while offering high temperature stability.

6. Chemically Induced Swelling

What Is it and What Causes It?

Chemically induced swelling occurs when there is an incompatibility between an O-ring’s material and its environment. The seal absorbs the media, growing in volume to the point of malfunction. The swelling may occur across the entire O-ring or only in the places exposed to the chemical. The swollen O-ring may extrude out of the seal grooves.

What Are Some Ways to Prevent It?

The only way to prevent this problem is to use an O-ring material chemically compatible with the system environment. Consult chemical compatibility charts, and don’t hesitate to consult a sealing material expert.

Kalrez® O-rings resist extreme volume swell when exposed to steam, sodium hydroxide, concentrated nitric acid, ethylenediamine, and many other chemicals and solvents.

7. Heat Hardening and Embrittlement

What Is it and What Causes It?

The leading heat-related causes of seal failure, hardening, and embrittlement occur when the application temperature exceeds the maximum temperature rating of the seal material. It can also occur due to excessive temperature cycling. The seal material hardens, and oxidation causes the seal to crack.

The surface of a heat-degraded O-ring may appear pitted or cracked, especially on the areas with the most exposure. This problem often occurs in conjunction with compression set due to a loss of elasticity, so the ring may appear flat.

What Are Some Ways to Prevent It?

Use an elastomer O-ring with high temperature resistance. Kalrez® FFKM o-rings deliver outstanding high temperature stability. Even after long-term exposure to temperatures up to 327°C, Kalrez® FFKM o-rings retain elasticity and recovery properties better than other high-temperature elastomers.

C&B Equipment Is a Licensed Kalrez® Distributor

C&B Equipment is proud to be a licensed distributor of Kalrez parts®. The superior performance of these seals helps you increase your uptime. Our goal is to eliminate your business’s downtime through top-of-the-line products and services. That goal is what we refer to as Uptime Solutioneering™.