A Guide to Centrifugal Pump Parts with Maintenance Checklist

You invested a lot of money in your centrifugal pump and want to ensure everything is always in great working condition in order to avoid losing valuable production time and money. If you invested in a high-quality product like ANSI centrifugal pumps, you already have a fantastic workhorse that requires very little maintenance but it is still important to educate yourself on the parts of the centrifugal pump and how to keep it running smoothly.

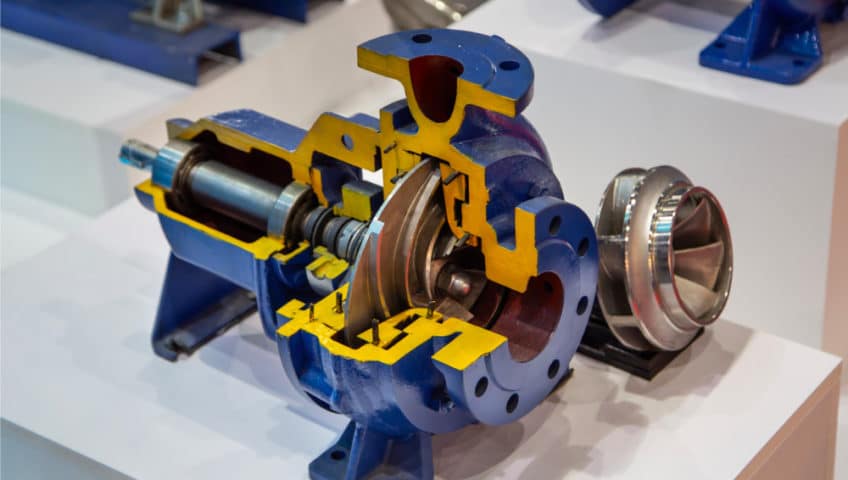

A Quick Overview of Centrifugal Pump Parts

A centrifugal pump has hundreds of components that make it run. We are going to discuss the main parts of the pump so you can better understand what you are looking for when you go through your maintenance checklist or have to troubleshoot issues.

Impeller

The impeller is a rotor that increases the kinetic energy of the flow. Impeller design will determine the performance of a centrifugal pump. A properly working impeller optimizes flow and maximizes efficiency.

There are three types of impellers:

- Open: Vanes are free on both sides. These are typically used in smaller, inexpensive pumps and pumps handling suspended solids.

- Semi-Open: In these impellers, vanes are free on one side and enclosed on the other. They are offer higher efficiencies than open impellers and can be used in medium-diameter pumps

- Closed: Vanes are located between the two discs in a single casting and are used in large pumps with high efficiencies. Pumps with closed impellers are the most widely used for handling clear liquids.

There are also different vane designs within the impeller but backward-curved is the preferred design due to the negative slope of the performance curve.

Shaft (Rotor)

This is where the impeller is mounted. The shaft is the mechanical component that transmits torque from the motor to the impeller.

Bearings

Bearings control the motion of the shaft and reduce friction between the rotating shaft and the stationary portion of the motor.

Shaft Sealing

This is exactly what it sounds like. Shaft sealing helps prevent the leakage of the pumped liquid. You always want to make sure the shaft is properly sealed to ensure that you are pumping the amount of liquid you are supposed to in order to continue efficient operation.

Casing (Volute)

The casing or volute is what holds the liquid that you are pumping and directs the flow of liquid in and out of the pump. This part of a centrifugal pump receives the fluid being pumped by the impeller and slows down the rate of flow.

If one of these parts breaks down or isn’t operating properly, you will need to look into the issue quickly to avoid permanent damage. Of course, you can try to troubleshoot and resolve the issue on your own but reaching out to the centrifugal pump experts at C&B Equipment will ensure that repairs are made correctly. If there is a bigger issue and the pump needs to be replaced, they will advise you on what the best centrifugal pump option is for your application.

If you have an ANSI centrifugal pump in your facility and need a new pump part ASAP, C&B Equipment can get into the warehouse 24/7/365 within two hours and get it shipped or ready to pick up.

Maintenance Checklist for Centrifugal Pumps

- Inspect Shaft Seals: Inspect shaft seals for physical signs of damage/leakage and replace the damaged seal as needed.

- Electrical testing: See that all electrical/electronic parts (motors, switches, etc.) in good working condition and operating correctly.

- Inspect Lubricant and Bearings: Follow the manufacturer’s guide for lubricant changes, lubricant type, and bearing operating temperature.

- Check for Vibrations or Loud Noises: This could be an indication of a mechanical issue and will need to be addressed as soon as possible.

- Examine the pump’s shaft alignment quarterly. A misaligned shaft could cause your pump to operate inefficiently or cause damage.

While you may feel under pressure to keep production going and costs down, ignoring issues or performing temporary fixes won’t prevent pump failure. If you are noticing your pump isn’t operating correctly, you should schedule a professional repair.

C&B Equipment offers pump repair and replacement, as well as regular maintenance to increase your plant uptime. Contact us today for more information.