Shaft Runout, Deflection, and Whip

Shaft runout, shaft deflection, and shaft whip are issues that can occur in industrial equipment that use rotating shafts. It is crucial that you check your machinery for shaft runout, deflection, and whip regularly. If left unattended, these three issues can lead to more severe problems with your equipment or, worse, total equipment failure.

What Is Shaft Runout?

What Is Shaft Runout?

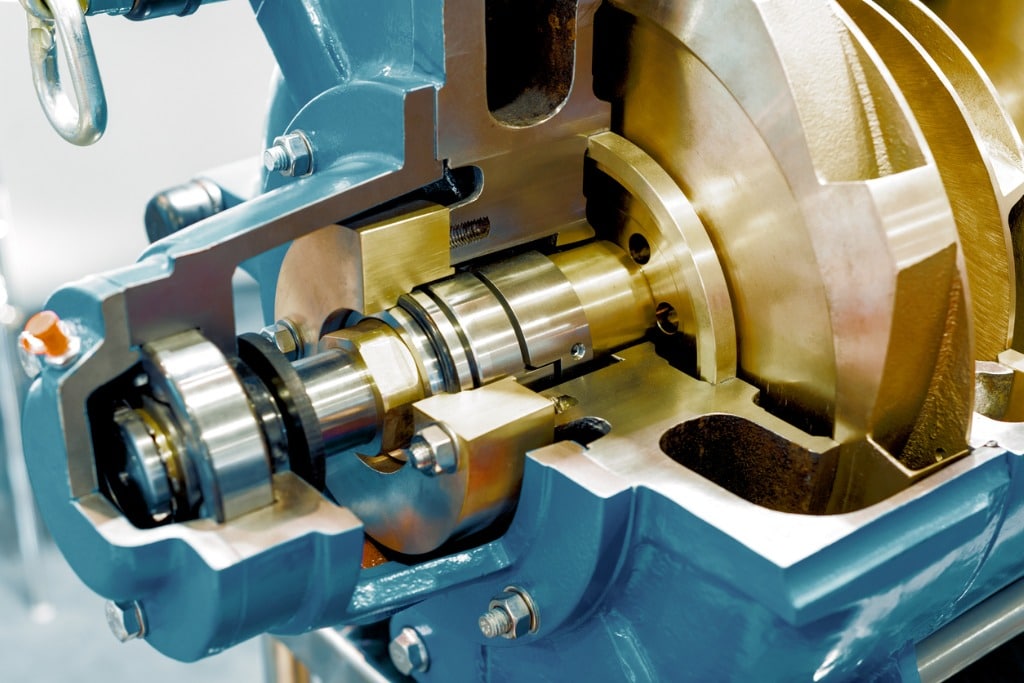

Shaft runout is the degree to which a shaft deviates from its true circular rotation. Every shaft has a center of rotation, often referred to as its centerline, and any stray from this centerline is considered shaft runout.

If shaft runout is severe enough, it can cause several problems with industrial equipment, including excessive vibration, seal wear, and bearing damage. Thankfully, it’s easy to check for runout before the alignment process begins by using a dial indicator and magnetic base.

Zero the indicator on the outside diameter of the coupling hub and slowly rotate the shaft. Watch for runout and measure the amount. Next, move the indicator to the shaft adjoining the coupling hub and measure it the same way. If the hub and shaft travel approximately the same amount, a bent shaft likely caused the runout.

What Is Shaft Deflection?

Shaft deflection occurs when a constant radial load in one direction causes your equipment’s shaft to bend downward. Whenever the shaft rotates 180 degrees, it continues to bend downward in a similar way. Four factors contribute to shaft deflection.

- Radial force in the impeller

- The length from the impeller to the radial bearing

- The shaft’s diameter (the smaller the diameter, the more deflection)

- The shaft material’s properties (different materials have different flex)

When you use a deflected shaft, it continues to rotate along its centerline even if the centerline isn’t straight. This rotation produces a “reversal of stresses” in the shaft that can cause the shaft to crack and eventually break altogether. You must limit shaft deflection in your equipment as much as possible to prevent internal parts from rubbing together.

If a shaft deflects too much, it will expose its rotating parts to its stationary parts. If your equipment uses stainless steel parts (many industrial pumps use stainless steel parts), these parts will begin to gall as soon as they make contact with each other. Galling almost always becomes progressively worse, and if left untreated, it can cause a complete seizure of your equipment’s rotating elements.

What Is Shaft Whip?

People often confuse shaft deflection and shaft whip. Radial load causes shaft deflection, whereas shaft whip results from issues with your equipment’s rotor. Shaft whip occurs when the shaft shifts 180 degrees from its centerline every rotation, creating a cone shape. Unbalanced impellers typically cause this shift because that’s where the highest velocity energy usually occurs.

C&B Equipment Can Repair and Maintain Your Industrial Equipment!

If any of your industrial equipment is suffering from shaft runout, shaft deflection, or shaft whip, reach out to C&B Equipment, and we will do our best to fix the issue. We offer preventative maintenance and repair programs to keep your equipment running in top shape. Shaft runout, deflection, and whip can lead to severe problems in your equipment if left unattended, costing you thousands of dollars in repairs and replacements. You must address these issues as soon as possible, and C&B Equipment can help you do so.