Reduce Your Energy Costs with Variable Speed Air Compressors

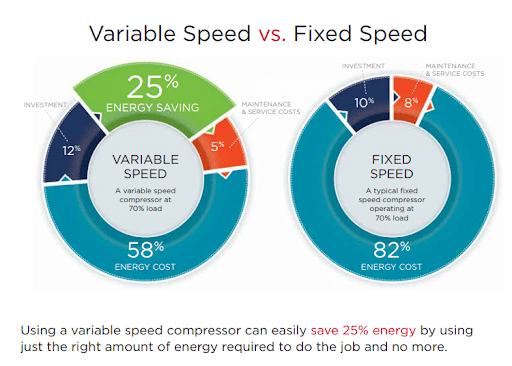

The most expensive aspect of utilizing an industrial air compressor is the energy that is required to run it. The cost of an air compressor’s energy consumption will far surpass the initial investment and maintenance costs over the course of the air compressor’s lifetime. Compressed air production can account for around up to 20 to 40% of your plant’s total energy bill.

If you are looking for ways to save on energy costs and maximize the efficiency of your industrial plant, reducing the energy consumption of your compressed air systems should be one of your top priorities. Regular maintenance and repairs are important, but the story begins with the compressor itself.

Using the right type of compressor for the right application can deliver significant energy savings and a consistent air supply. Gardner Denver’s rotary screw air compressors are more than capable of meeting the demands of your plant and can reduce the amount of power that is needed during downtime, thanks to their variable speed drives.

Fixed vs. Variable Speed Air Compressors

Industrial air compressors can be classified as either fixed speed or variable speed. Sometimes referred to as idling compressors or load/unload compressors, fixed speed air compressors run at a fixed RPM.

If air is required, the inlet valve opens up a bit. If not, the inlet valve closes. The motor doesn’t ramp up and down as air demand fluctuates. It’s either at full throttle or off.

If air is required, the inlet valve opens up a bit. If not, the inlet valve closes. The motor doesn’t ramp up and down as air demand fluctuates. It’s either at full throttle or off.

This is perfectly fine if your application requires a constant supply of compressed air. However, most applications do not. Most applications require a fluctuating demand, meaning the unneeded energy is wasted. This is where variable speed drive compressors can provide significant energy savings.

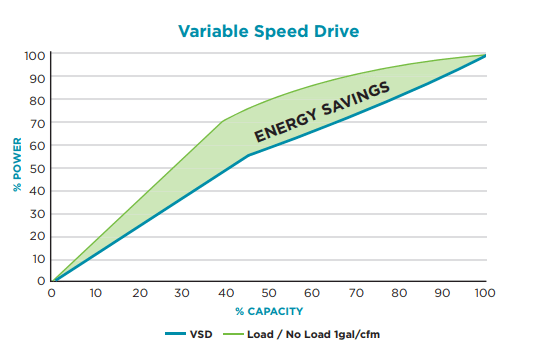

This type of compressor utilizes variable speed drive (VSD) technology that allows the motor to ramp up and down to match the demand. The most common type of VSD technology used in air compressors is the variable frequency drive (VFD), which varies the frequency and voltage that is supplied to the motor.

A VSD air compressor that has a horsepower of 100 can reduce its power to around 20 horsepower when the demand for air is low, saving energy in the long run. Using a variable speed compressor can easily save on energy costs by using just the right amount of energy to meet the demand and no more than that. Depending on the application, energy savings can be as high as 50%.

Gardner Denver’s Variable Speed Air Compressors Ramp Up the Energy Savings!

Gardner Denver has been at the forefront of compressed air technology for decades and offers some of the most energy-efficient and environmentally friendly rotary screw compressors available on the market today. They offer multiple air compressor lines that utilize variable speed drives.

Gardner Denver LRS Series Variable Speed Compressors

LRS Series single stage compressors provide world-class energy efficiency through the use of robust inverter drive systems, which precisely match power consumption with air demand. The clean and simple machine layouts reduce piping, which cuts down on the opportunity for energy-wasting leaks.

Gardner Denver VST Series Two-Stage Compressors

Gardner Denver VST air compressors offer all the benefits of the VS Series in a two-stage model—employing 8-12% more efficiency than single stage models. These compressors operate using two motors and two air-ends for optimum performance. The technology employed in the airend rotor profiles synchronizes the speeds and performance of the first and second stage airends to optimize the performance and energy efficiency.

EnviroAire TVS Series Oil-Free Compressors

EnviroAire TVS compressors efficiently and reliably handle varying air demands with a matched motor, direct drive, and air-end. These oil-free compressors deliver no oil into the air stream and minimize microbial content through high-temperature compression to reduce product contamination risk.

EnviroAire VS Series Oil-Free Compressors

EnviroAire VS Series two-stage compressors contain absolutely no oil anywhere in the compressor and have been certified ISO 8573-1 Class Zero (2010) and silicone-free. They provide you with a clean, reliable, efficient, and cost-effective air supply with no risk of oil contamination.

Is a Variable Speed Air Compressor Right for Your Application?

When correctly sized and implemented for the proper application, variable speed compressors have the potential to deliver significant energy savings. However, they also have a considerably higher upfront cost.

Plants with fluctuating air demand—whether from seasonal production changes or differing levels of air demand across shifts—can often justify the higher cost of variable speed over single speed compressors due to the sustained energy savings. Plants may also qualify for energy incentives and credits for implementing energy-saving technologies.

Plants with fluctuating air demand—whether from seasonal production changes or differing levels of air demand across shifts—can often justify the higher cost of variable speed over single speed compressors due to the sustained energy savings. Plants may also qualify for energy incentives and credits for implementing energy-saving technologies.

There are other considerations as well. Variable speed compressors are sensitive to power inconsistencies. If there are any concerns in this area, data logging should be done to ensure power consistency before deciding on a compressor. The sensitivity of VSD drives also makes them susceptible to dirty and wet conditions, requiring extra protection.

A professional compressed air audit is the best way to determine if a variable speed compressor is appropriate for your application and if it will deliver you worthwhile cost savings.

Recommended Read What Causes Oil Carry-Over in Compressed Air Systems?

C&B Equipment Is a Licensed Distributor of Gardner Denver Compressed Air Systems

C&B Equipment is proud to be a licensed distributor of Gardner Denver air compressors. These compressors’ efficient and reliable performance will help you increase your uptime—the mission that dictates everything we do.

If you are in the market for a variable speed air compressor, take a look at our selection. Additionally, we also offer air compressor installation, maintenance, and repair services and perform air audits to determine if your plant could benefit from improved air quality or reduce its energy consumption.